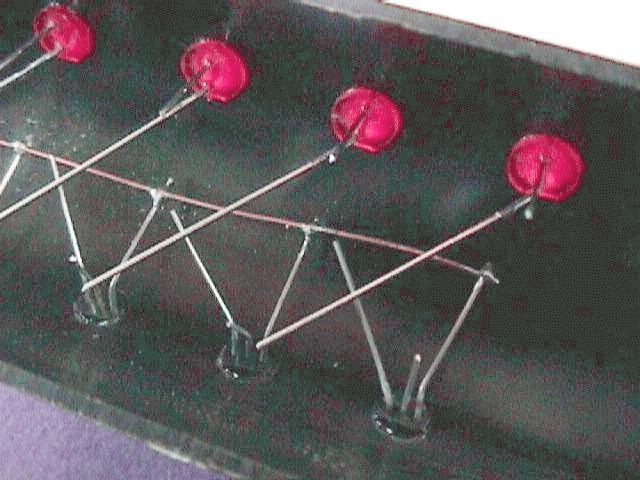

of pins 18 - 25, as they are all connected to ground via the parallel port.) Connect the strain relief clamp (as shown) and attach the plastic case to the DB25 plug. (The plug kit contains two screws and shaped metal tabs that allow the DB25 connector to be semi-permanently held in place. Since your LED Bar will typically be a temporary connection, you can discard these parts.)

of pins 18 - 25, as they are all connected to ground via the parallel port.) Connect the strain relief clamp (as shown) and attach the plastic case to the DB25 plug. (The plug kit contains two screws and shaped metal tabs that allow the DB25 connector to be semi-permanently held in place. Since your LED Bar will typically be a temporary connection, you can discard these parts.)To find the address of the LPT1 port on a PC, use DEBUG. At a DOS prompt, type debug. You will get a minus sign, (not blinking) at the left edge of the screen which is the debug prompt. Type the following (with no spaces): d40:0008 and hit enter. You will see something like:Convert your hex number to decimal. For example: 0378 = (8 x 1 = 8), + (7 x16 = 112), + (3 x256 = 768). 8 + 112 + 768 = 888.

0040:0008 78 03 00 00 00 00 00

and several more lines of similar numbers and letters. This is a "hex dump" of the contents of the eight memory locations starting with 40:0008. The first pair of numbers (78 03) is the base address of LPT1. The number pair 78 03 is the hex number 0378h. The 78 and the 03 are reversed because Intel stores sch numbers in a 'low byte-high byte' format. If only one printer adapter is stored, the following numbers will be 00 00 etc. If your PC has an LPT2, and/or LPT3 installed, there will be other pairs of numbers on the 0040:0008 line. You can exit debug by typing q.

| Item | Stock # | Cost |

| LED's | 279 55-552-0 | $11.83/100 |

| Transistors | 111 2N3904 | $ 0.14 each |

| Carbon Film Resistors | 353 CR25 2.2K | $ 1.00/100 |

| Carbon Film Resistors | 353 CR25 10 | $ 1.00/100 |

| DB25 plug | 279 30-112-0 | $ .75 each |

| DB25 hood | 279 30-132-0 | $ .57 each |

| Beldon flat cable (10 conductor) | 9L28010 | $14.00/100 feet |